Copper Recovery Cable Recycling Equipment

INDUSTRIAL SCRAP RECYCLING EQUIPMENT FOR THE RECYCLED MATERIAL INDUSTRY

Copper Recovery stands as a premier manufacturer specializing in wire and cable recycling equipment, extending our reach globally with comprehensive sales and service offerings. Additionally, we serve as esteemed representatives for select European manufacturers renowned for their excellence in recycling machinery.

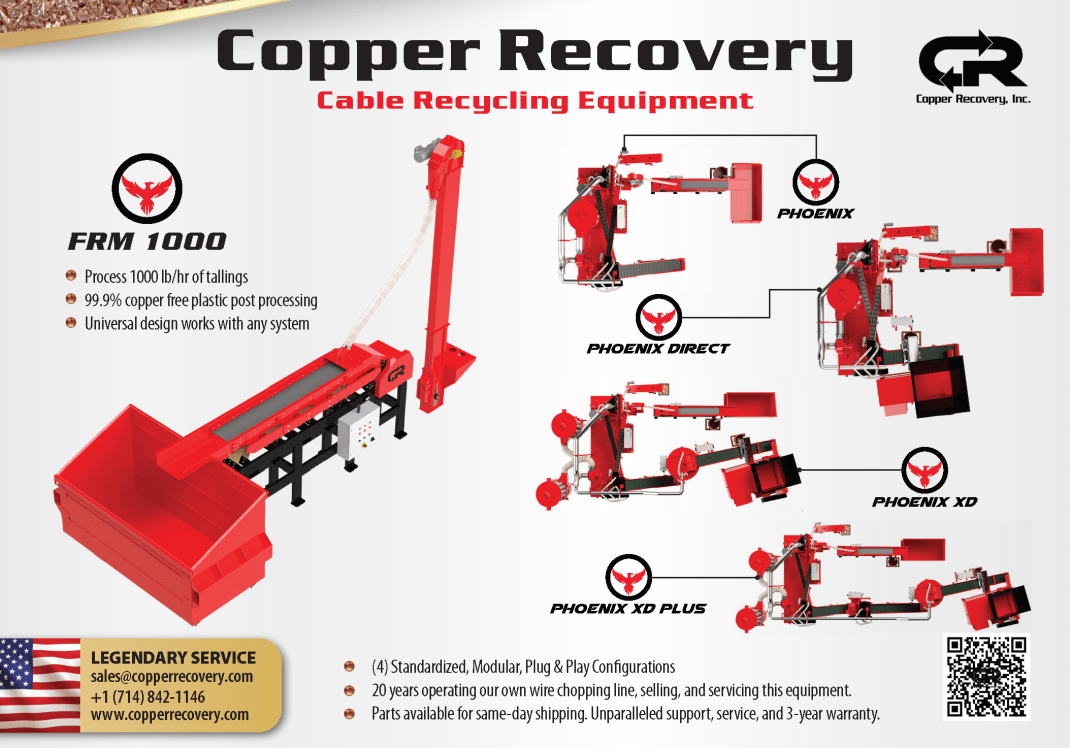

Drawing upon two decades of expertise in cable recycling, we’ve recently unveiled our latest innovation, the Phoenix series. This modernized line of wire chopping equipment integrates our extensive knowledge, proven methodologies, and substantial re-engineering efforts, resulting in four modular configurations tailored to diverse processing capacities and budgets.

UNIVERSAL SHREDDERS FOR EVERY BUDGET AVAILABLE IN A WIDE RANGE OF SIZES

Wagner Shredders have earned a distinguished reputation in the industry for their exceptional robustness, unwavering reliability, and continuous commitment to cutting-edge innovation. Renowned globally, Wagner stands as a beacon of quality and excellence in the realm of shredding technology. What sets Wagner apart is its extensive range of shredders, each crafted with precision and expertise to cater to a wide array of processing needs. From scrap insulated cables and e-waste to plastics, wood, textiles, and even medical waste, Wagner's shredders are engineered to handle diverse materials with ease and efficiency. This versatility makes Wagner a trusted choice for the recycled materials industry, manufacturing, waste management, and beyond. Furthermore, Wagner understands the importance of certainty when it comes to shredding compatibility. That's why they offer a complimentary sample testing service, allowing clients to assess the suitability of their materials for shredding without any obligation. This invaluable service provides peace of mind and ensures that clients can make informed decisions regarding their shredding needs. In essence, Wagner Shredders epitomize excellence in shredding technology, combining durability, reliability, versatility, and innovation to empower industries worldwide. With Wagner, clients can trust in superior performance, tailored solutions, and unwavering support every step of the way. Copper Recovery exclusively employs Wagner Shredders for these reasons.

CABLE RECYCLING EQUIPMENT STANDARDIZED - MODULAR - EXPANDABLE

Copper Recovery proudly presents Phoenix, an exceptional series of cable recycling lines designed to revolutionize recycling operations. Often referred to as "wire choppers," "granulation plants," or "cable granulators," Phoenix stands at the forefront of innovation in the field. What sets Phoenix apart is its remarkable processing capability and exceptionally efficient separation. Ranging from 2000 to 4000 lb/hr, Phoenix systems are powerhouses in the recycling industry. Despite their high throughput, Phoenix is ingeniously engineered to occupy minimal floor space, maximizing efficiency without sacrificing productivity. Moreover, Phoenix offers versatility beyond compare, Phoenix empowers recycling operations to tackle diverse cable mixtures with ease. Phoenix represents the pinnacle of wire chopping technology, combining cutting-edge design with unparalleled performance to redefine the standards of recycling efficiency and sustainability.

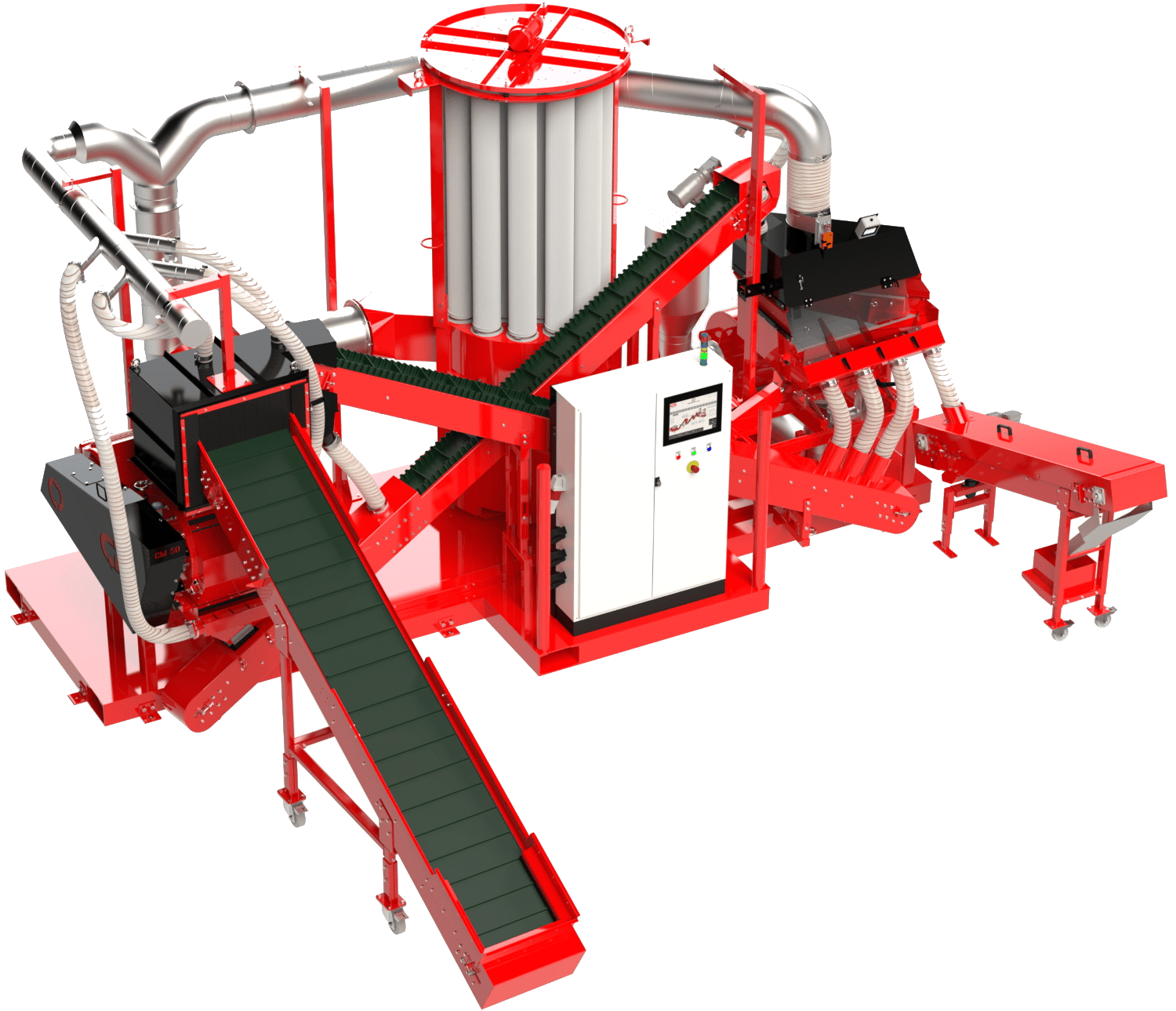

DELAMINATION TECHNOLOGY FOR PCB / E-WASTE / PM RECOVERY AND DIFFICULT MATERIALS

With its foundation deeply rooted in mineral processing, UMS, or "Urban Mining Solutions," draws upon 25 years of expertise in refining and advancing existing technologies to create innovative recycling solutions. UMS specializes in the development and application of cutting-edge technologies for recycling various materials. From Hard Aluminum to PCBs, PM (Precious Metals), E-Waste, and Mixed Metals, UMS offers complete plant solutions and field-proven methodologies for efficient delamination, processing, and recovery. Through years of hands-on experience and continuous innovation, UMS has established itself as a leader in sustainable recycling practices, providing comprehensive solutions that address the complexities of modern material recycling challenges.

WIRE CHOPPING

Maximize ROI with our low cost, industrial grade equipment that will serve your needs for decades.

PLASTICS RECYCLING

Size reduction. Separation by polymer or color. If you want to recycle plastic, we have proven solutions.

WOOD

Mixed wood & metal separation. Resource recovery. Wood is renewable energy! Our shredders and separators get the job done without breaking the bank.

E-WASTE

Entire turn-key plants and components available for every stage of the process. German engineered plants. Proven technology already operating for many years.

RADIATOR PROCESSING

A niche that offers a very nice value upgrade for clean copper / aluminum radiators.

TEXTILE

Secure desctruction by shredding your goods bevore they goto the black market.

WE ARE YOUR ADVANTAGE.

Providing legendary service for over 20 years, Copper Recovery is, not only the premier manufacturer of wire chopping lines, but also agents for the finest European recycling equipment available. Plus, Copper Recovery is unique in that we run the processing equipment we sell!

Our facility is available for sample testing, production testing, and R&D testing. We use our equipment not only for our own processing but for demonstration and testing. Contact us today to arrange for a test of your material!

Quality Testing

Hot Offers

European quality at an unbeatable price with American service and support.

Stand Alone Units

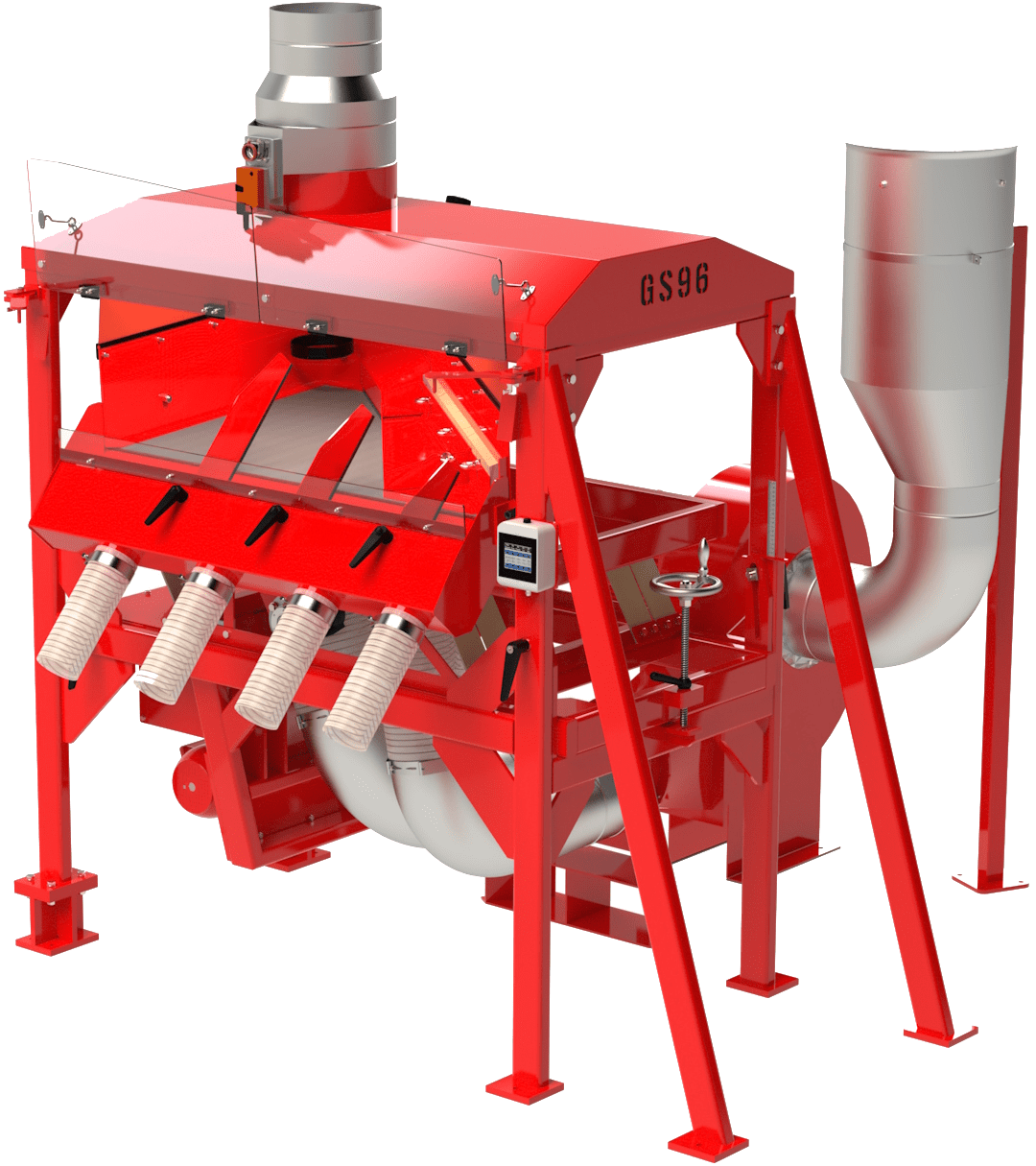

Our system components are available as standalone units, offering the versatility needed for integration into existing plants, customized configurations, or newly engineered processes. The hallmark of our efficient separation technology lies in its flexibility, enabling the production of pristine output products. Our separators are engineered with minimal moving parts, ensuring low maintenance requirements and optimal performance. They are perfectly suited for processing all types of dry wires, including copper and aluminum, as well as combinations of the two. Whether it's copper alone or copper mixed with aluminum, our separators deliver exceptional results. Beyond providing top-notch equipment, we go the extra mile by sharing our expertise and guiding you on how to not only operate but also maximize the potential of your new equipment. For example, the GS96 Gravity Separator, as depicted, comes with integrated features such as a blower and intake air filter, showcasing our commitment to seamless functionality and user convenience.

Looks can be deceiving.

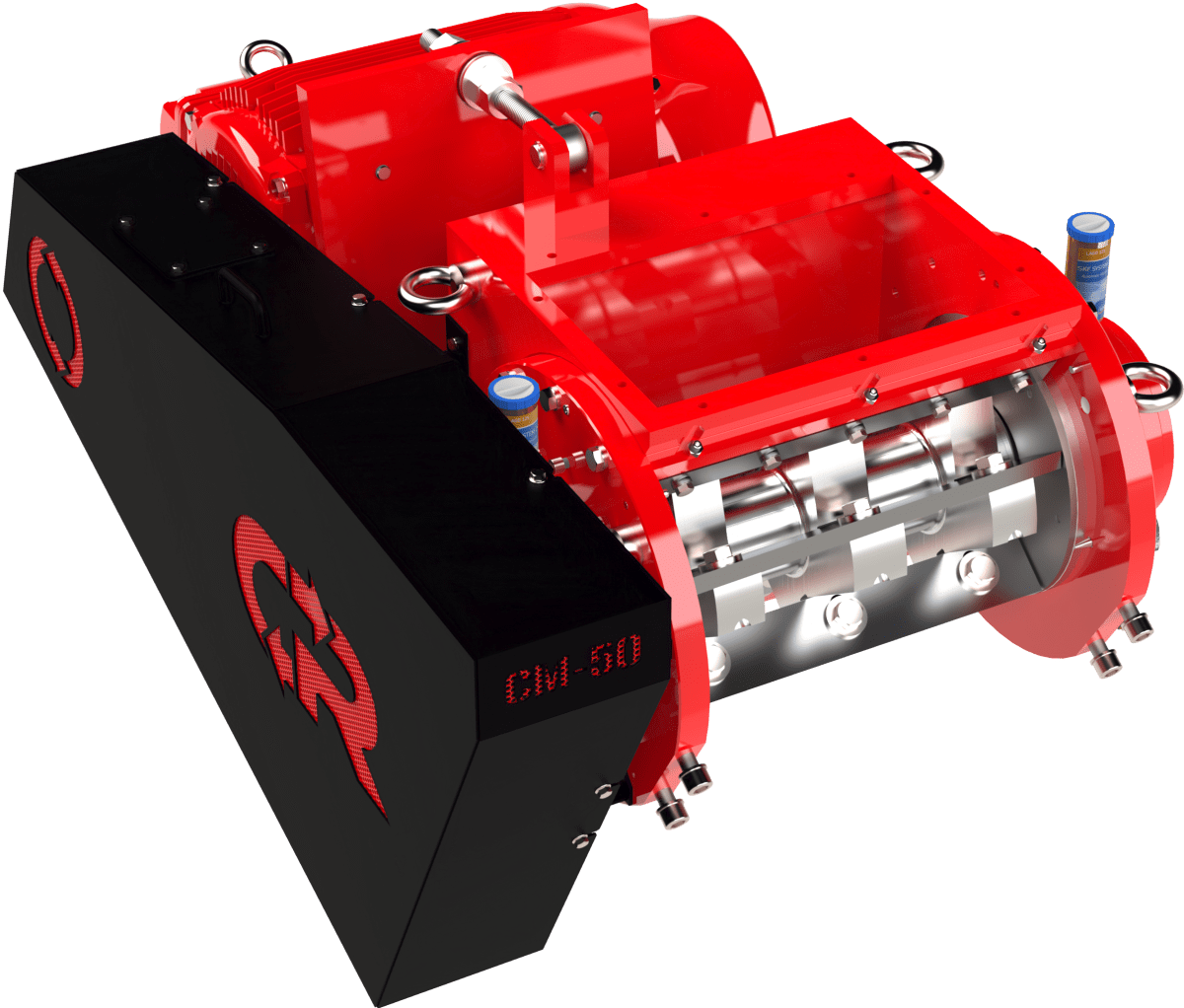

Quality is more than skin-deep! Our industrial-grade equipment is meticulously engineered to endure even the harshest conditions for the long haul. Combining processing expertise with advanced engineering, every aspect of the CM50 Cutting Mill is crafted for durability and performance excellence. From specialty forged alloy components to replaceable HARDOX® wear-resistant linings, our equipment is designed to withstand rigorous use and deliver consistent results, ensuring reliability and longevity in your operations.

Quality Assured. ISO:9001 manufacturing process is folowed strictly to ensure consistency and reliablity.

SHREDDING

CABLE RECYCLING

WEEE & E-WASTE