Wagner - The Ultimate Cable Recycling Shredders

WAGNER

MECHANICAL ENGINEERING WITH TRADITION.

Quality, power and endurance Made in Austria. These properties typify all Wagner shredders. Shredders are always optimized to your specific or special requirements. When you need more of everything, we build your special shredder exactly as required. Unique solutions are our specialty.

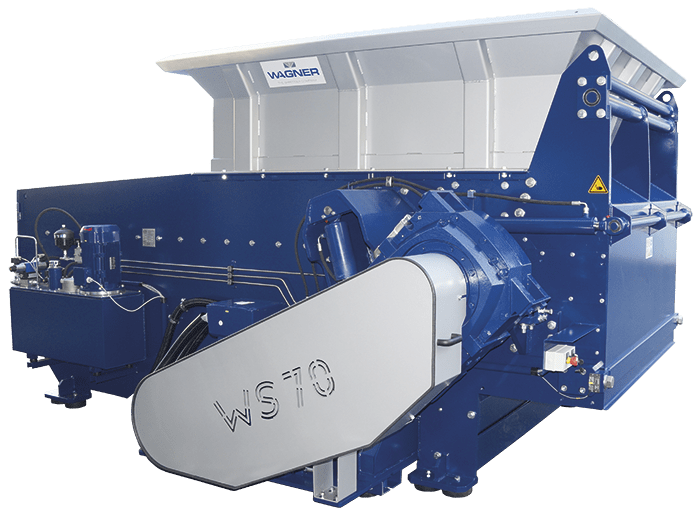

WS70

Voluminous and difficult to shred materials are no problem for this model. Comes with a 12" touch panel featuring 10 pre-programmed one touch parameter selection of presets to get the most out of the shredder for any given input material at any given time. All models feature bolt-in bolt-out removable knife holders for ultimate servicability. When you need the biggest and best, choose WS70.

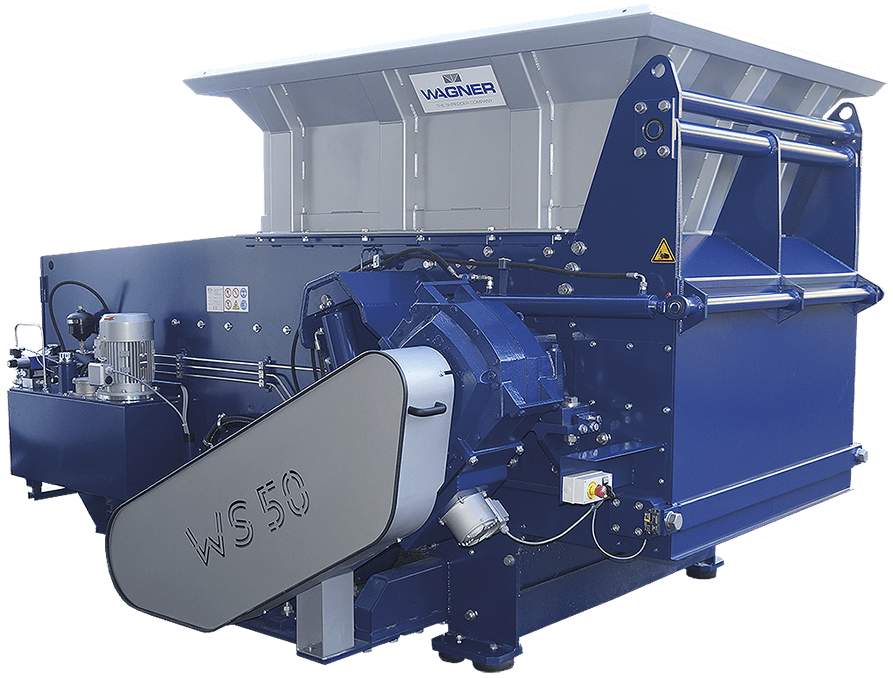

WS50

Plastics, wood, scrap cables, the powerful solution for various recycling materials and requirements. Comes with a 12" touch panel featuring 10 pre-programmed one touch parameter selection of presets to get the most out of the shredder for any given input material at any given time. All models feature bolt-in bolt-out removable knife holders for ultimate servicability.

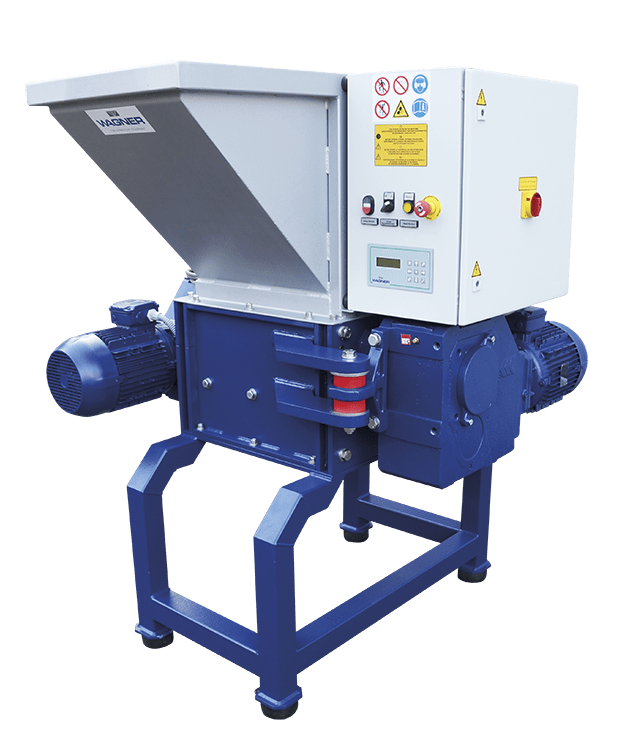

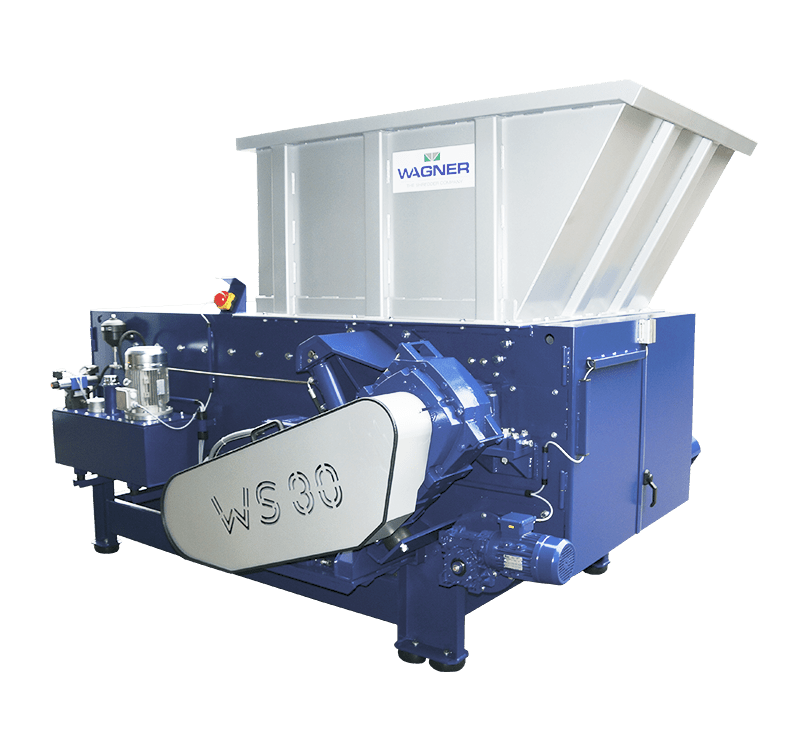

WS30

Almost all shredable materials can be shredded effectively and economically with the WS30. Our best selling model, WS 30 offers best in class price to performance with rapid ROI. Featured on the front end of the Copper Recovery PHOENIX XD and PHOENIX XD+ wire recycling mini-plants, the WS 30 is the true workhorse of many wire chopping plants in operation daily in the USA and worldwide.

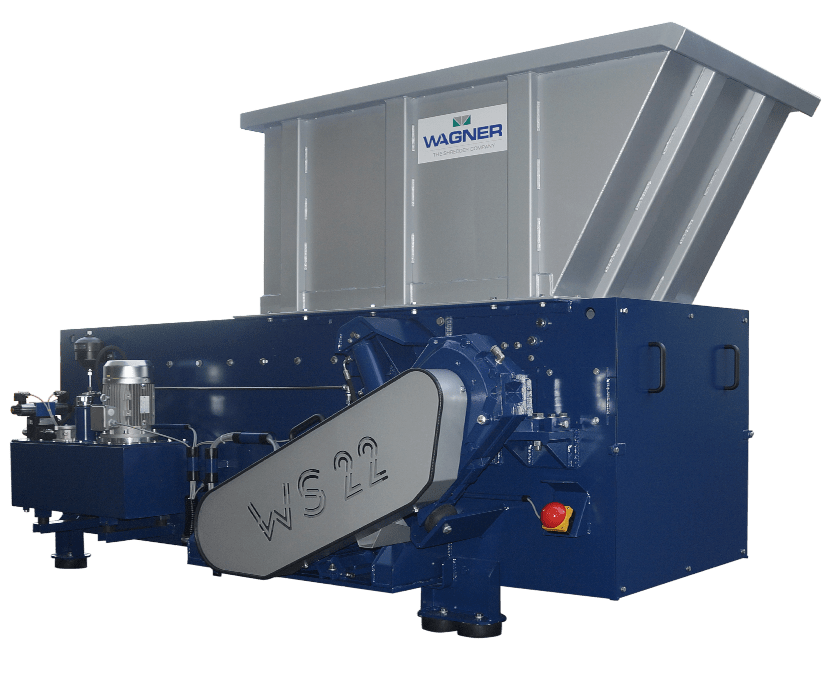

WS22

The shredder that started it all. 20 years on the market, the constantly developed WS 22 shredder can handle everything the larger WS 30 can, but features a shorter rotor and less working area. Let us specify the best motor size for you application. This universal shredder can be fitted with motors from 18.5 - 45kW, or 25 HP - 60 HP. If you are on a tight budget but have a tough application, WS 22 is a no compromise affordable shredder.

WS11-15

If you have material that isn't bulky or have a low throughput processing requirement, the WS 11, or WS 15 gets the job done! Engineered for durability yet affordability, the WS 11-15 are the most economical shredders available for all kinds of material including plastic waste, foils, purgings, scrap wire, electronic scrap, wood waste, paper, cardboard, textiles and more. Choose between 10 different programs on the PLC operated keypad.

ProCut Series

Number of knives: 84 Drive power: 1 x 75 kw / 1 x 90 kw . All sorts of plastic waste (hard and soft, cluster, automotive, foils, etc) electric cables, electronic scrap all sorts of wood waste paper and cardboard boxes textiles and many more.

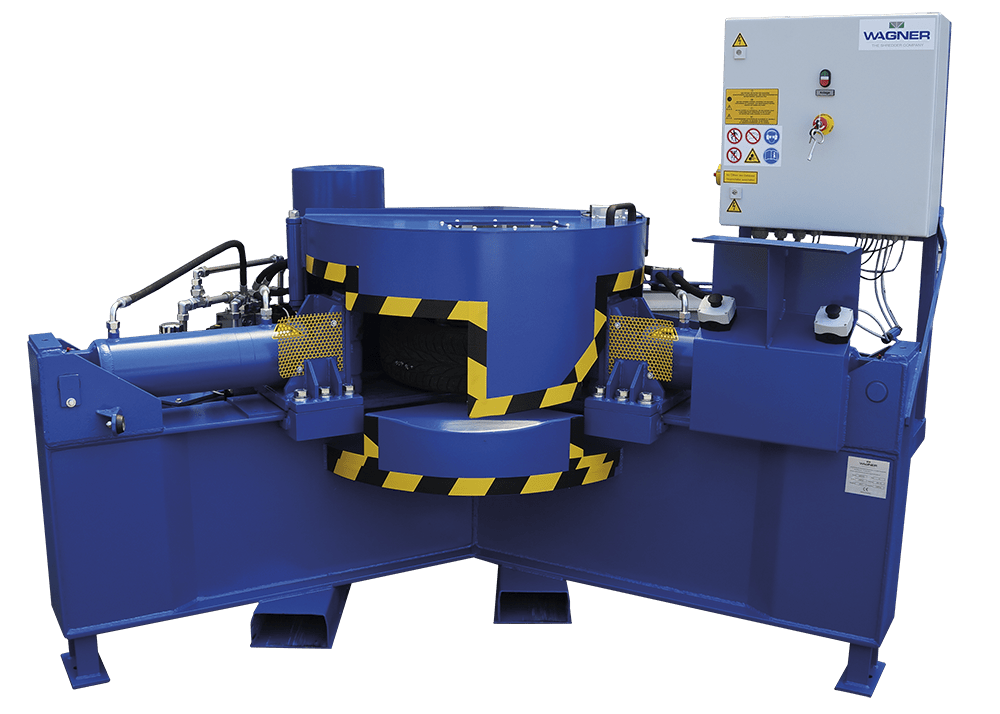

DISMANTLER FOR TIRES

Special Machines like this glass bottle breaker for size reduction are available! Turn your dream machine into a reality! Custom purpose machines build on request.

ProShred Series

The pre-sorted material to be chopped is fed into the two shafts whose rotors are moving slowly in opposite directions (therefore dust and noise free). The cutting discs are plugged on the shaft.This process is controlled by an intelligent and innovative PLC. In case the machine is overloaded or foreign objects are in the cutting unit, the rotor stops and moves backward (return overload behaviour and reverse running). The precisely serrated fixed knives make sure the material is shredded with a minimum of power. The fastened wiper element helps to avoid multiple turn coiling and raising of the material to be chopped.

TWIN SHAFT SHREDDER WTS500

MORE THAN 30 YEARS OF EXPERIENCE IN THE CONSTRUCTION OF SHREDDERS has contributed greatly to the development of this category of WTS shredder models.

Material to be chopped is fed into the two shafts whose rotors are moving slowly in opposite directions (therefore dust and noise free). The cutting discs are plugged onto the shaft. This process is controlled by an intelligent and innovative PLC. In case the machine is overloaded, or foreign objects are in the cutting unit, the rotor stops and moves backward (return overload behaviour and reverse running). The precisely serrated fixed knives make sure the material is shredded with a minimum of power. The fastened wiper element helps to avoid multiple turn coiling and raising of the material to be shredded. The number of the knives or their width respectively determines the size of the output material. This sturdy machine is designed for longevity; along with hazardous waste it economically processes electronic scrap, circuit boards, sheet metal, sheet metal barrels, all sorts of containers for industrial waste, plastic waste production waste, binder, paper and cardboard boxes, electric cables, metal sheet food, food remains, biogenic waste, wood glass, plastic waste, various containers for liquids, etc.

With a rich variety of options for feeding and carrying away the material, special funnel shapes, and different machine base-frames the shredder is ideally adjustable to individual requirements.

Advantages:

*low maintenance solid add-on system to be bolted together

*two gear system, therefore constant torque mode on both shafts

*user-friendly innovative PLC and screen

*potent and reliable

*high availability due to a high quality standard

*knives can be exchanged easily and quickly

*robust design

GO AHEAD. SHRED IT!

INNOVATIVE FEATURES

SMART TOUCH PANEL

High performance, field proven. One touch, user friendly 12" touch panel is available. 10 pre-set, field adjustable routines maximize material throughput while optimizing energy efficiency.

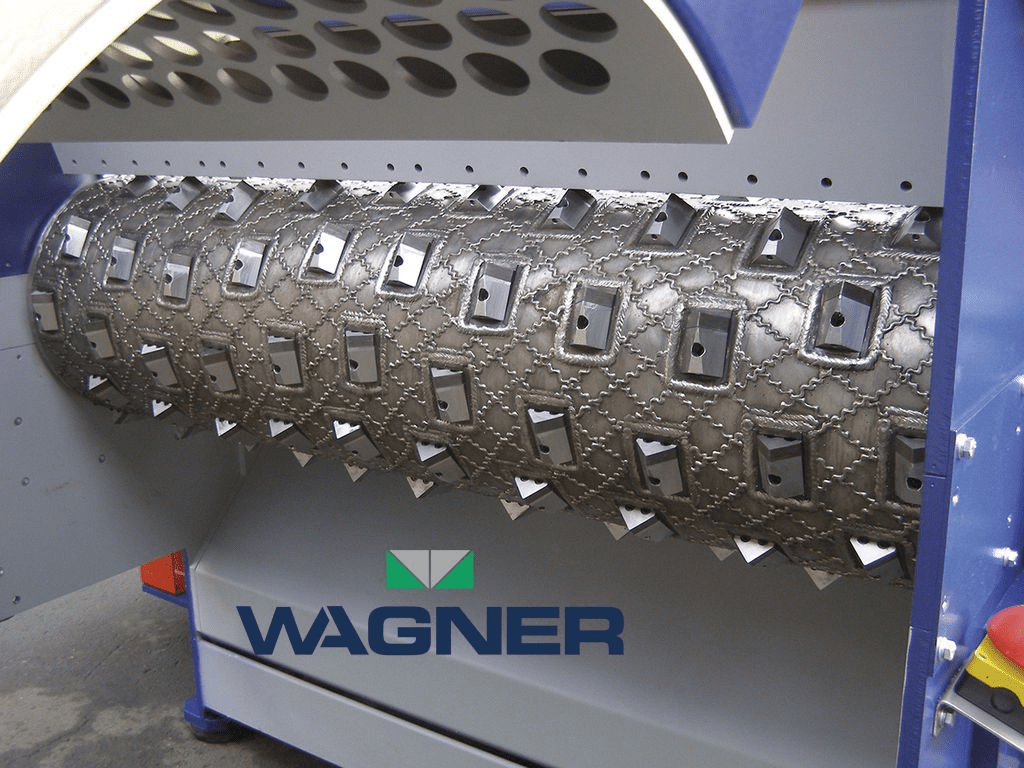

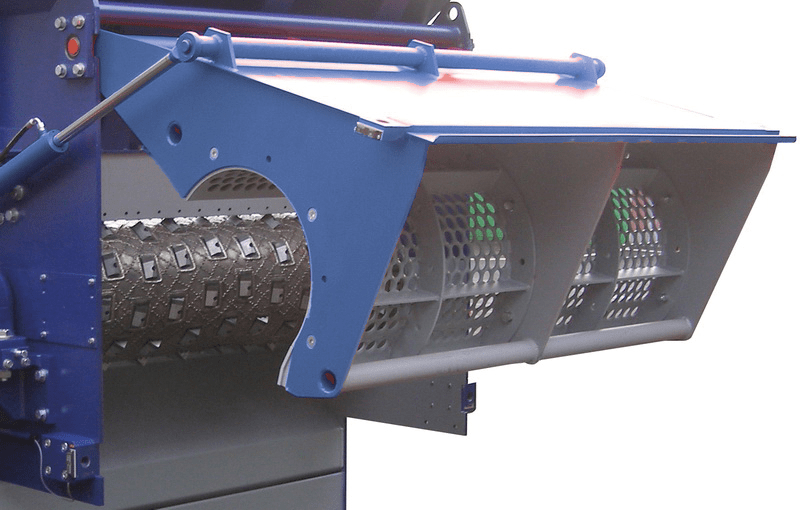

ROBUST ROTOR DESIGN

Optional solid tungsten carbide knives shown here make short work of the toughest material. Hollow rotor design with hard-facing wear seams feature bolt-in bolt-out knife holders for simple maintenance, reduced operating costs and maximum uptime.

EFFICIENT DRIVE SYSTEM

Each shredder comes configured with the ideal motor, drive ratio and overall configuration to perfectly suit your processing requirement.

EASY MAINTENANCE

Hydraulically opened door allows for ultra fast maintenance. High availability of machines and parts. We can quickly supply your shredder and maintain local inventory of parts. We are ready when you are.