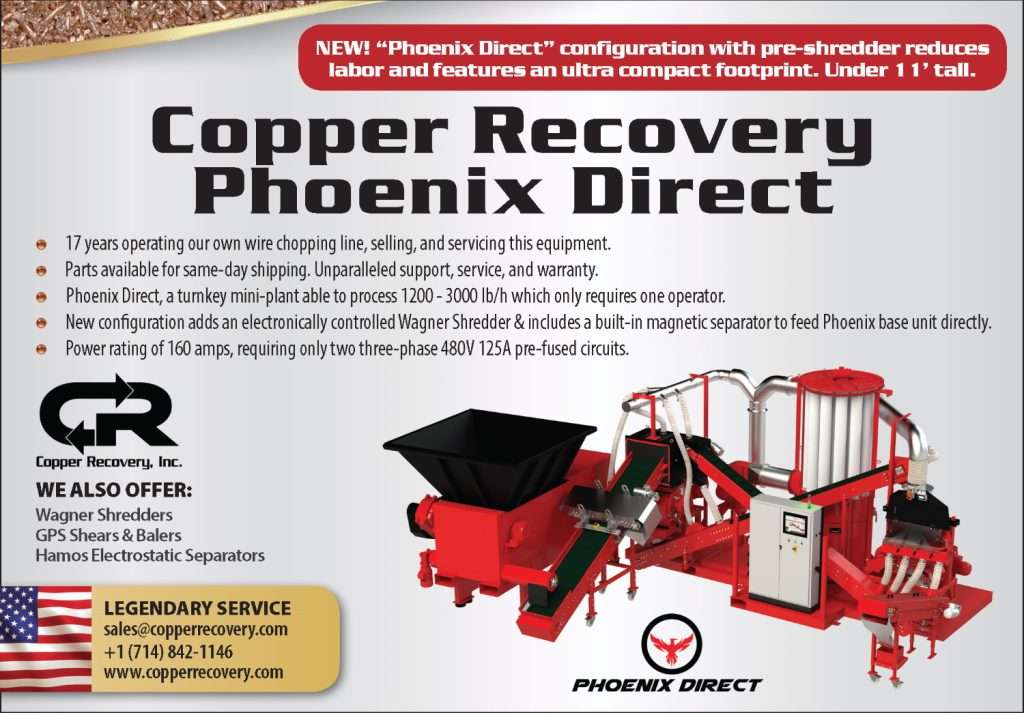

Copper Recovery Launches new configuration "Phoenix Direct"

Copper Recovery's Beau Janzen weighs in on critical factors for recyclers considering purchasing wire chopping equipment

Read about some factors to consider when entering the wire chopping market in the current economic climate surrounding cable recycling.

Copper Recovery in Recycling Today Article

Read what the authorities on the topic have to say about wire chopping back in 2018.

APRIL 4, 2016

Copper Recovery announces the Phoenix Cable Recycling System

Copper Recovery is excited by the news. “With over a decade of running a wire chopper, as well as selling and servicing them, we are uniquely positioned to make the best-in-class product for our customers,” says CEO Christopher Carlson. “We will continue to support our customers’ investment into the future with parts and equipment, but will now also produce what we believe to be a higher quality, updated, and more powerful model.”

Copper Recovery’s new manufacturing partner holds multiple quality certifications including ISO 9001, ISO 14000, and a very long list of welding certifications. They are also certified by multiple third party companies that validate the safety, reliability, and quality of products. These include, TUV, GLC, IQNet, and UNIcert. Quality, reliability, and consistency are now hallmarks of the new Phoenix.

Copper Recovery is also excited to announce its new relationship with Reto Recyclingtechnik GmbH – Recycling Dortmund Maschinenbau, as well as, being the exclusive North American representative for Wagner Machinenbau GmbH (producers of Wagner Shredder).

Phoenix debuted in booth 2537 at the ISRI 2016 Convention & Exposition at Mandalay Bay Las Vegas on April 4, 2016. Cable recycling equipment production is ongoing and Phoenix plants are in serial production and often available for immediate delivery.

“I have spent my entire career in the scrap industry working with cable recycling plants, and we’ve channeled that knowledge into the Phoenix. We could not be more excited, as this is an accomplishment we can be proud of,” says Beau Janzen, Project Manager of Phoenix. “We’ve installed a lot of machines over the years and have a very tight network of customers. We knew exactly where to focus on reliability and durability. We’ve also been able to implement significant improvements. We also offer Phoenix XD, the expanded version with greater capacity, featuring a Wagner single shaft shredder.”

“We pride ourselves that our wear parts and spare parts inventory has always been complete, with same day shipping available. We will continue to provide parts for existing users into the future. We’ve also setup in-house financing as an option for equipment purchases, so customers have more payment options and can take advantage of the low rates available,” states Chris Carlson.

Contact ISRI at http://www.ISRI.org for convention information.