Cable Recycling

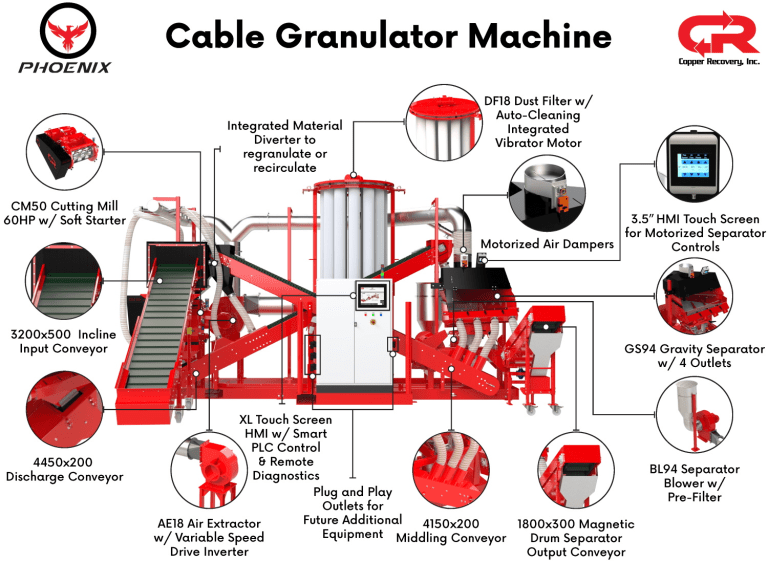

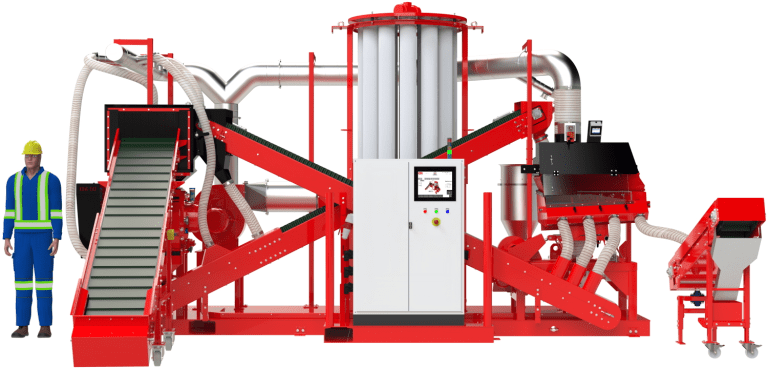

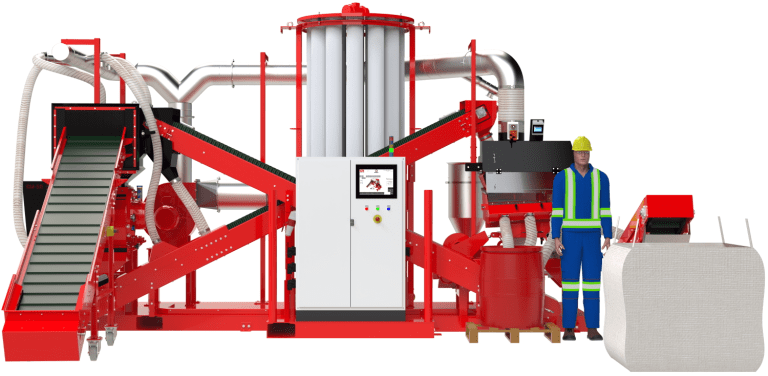

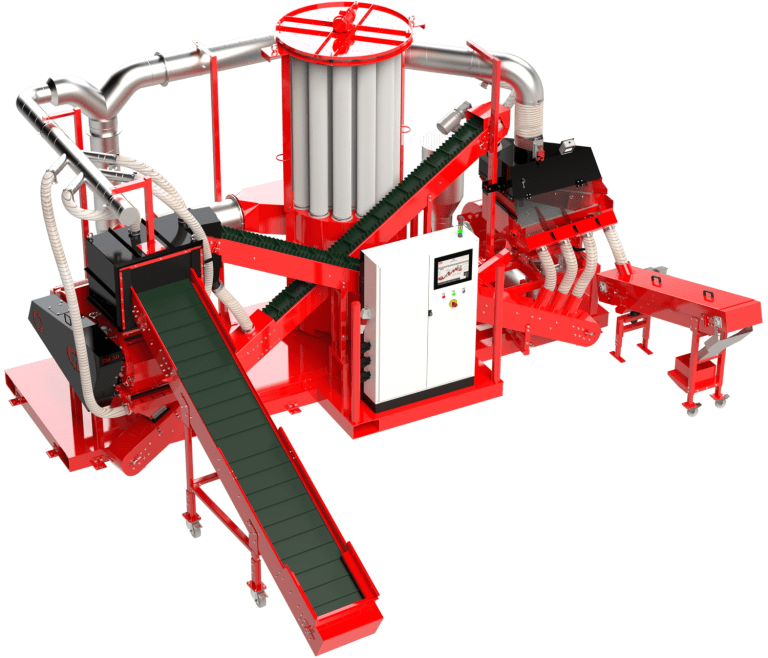

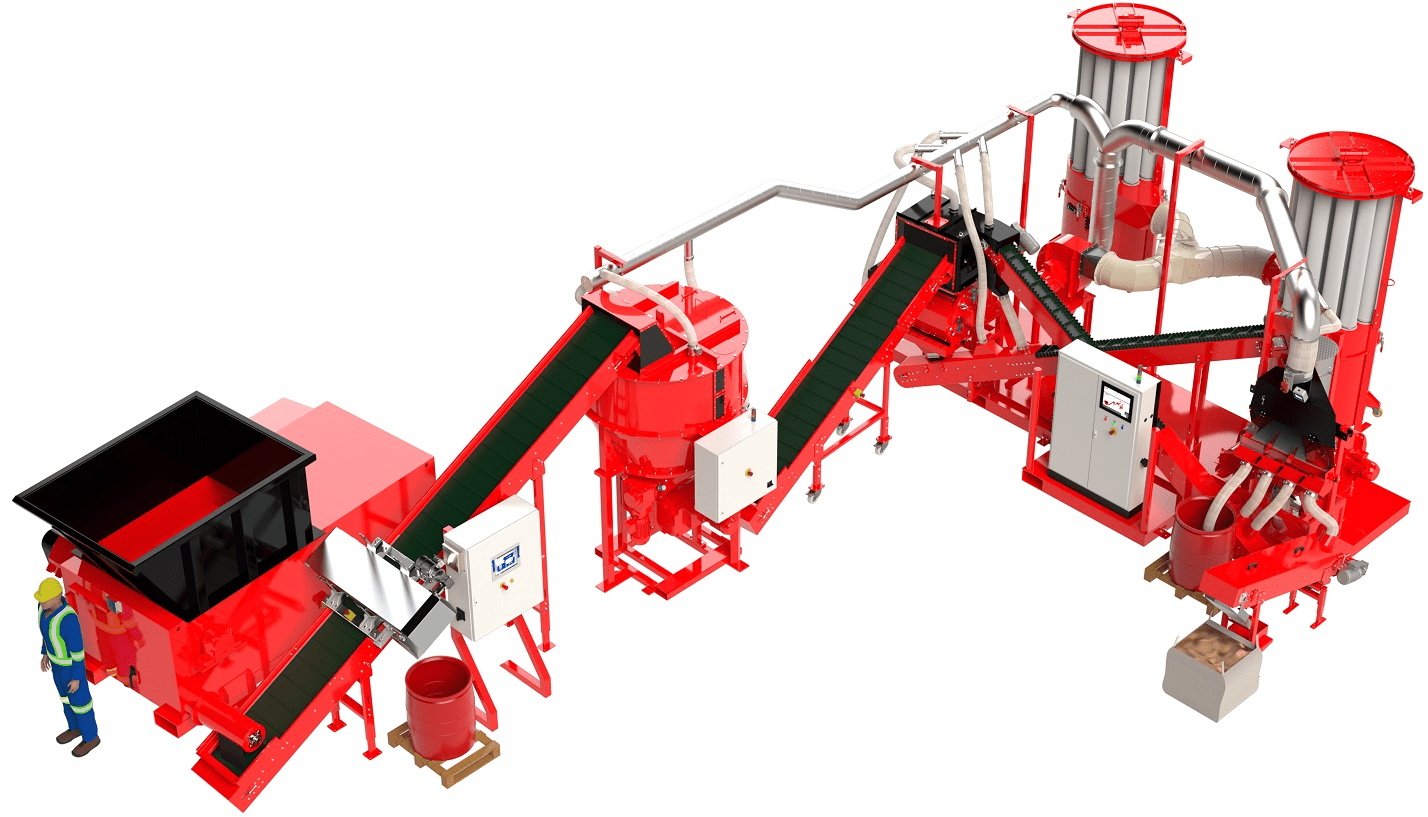

Introducing the Copper Recovery CM50 Cable Granulator—a precision-engineered machine meticulously designed for high-performance cable recycling, efficiency, and durability. Purpose-built for the task at hand, our Cable Granulator is a cornerstone of all Phoenix configurations. Contact us today to schedule your live demonstration of the complete Phoenix System and witness the power and efficiency of our cable reycling equipment firsthand.

Phoenix

Cable Recycling Mini-Plant

PHOENIX is a professional turn-key cable recycling machine with the substantial capacity to process *1,200-2,500 input lb/per hour with mixed cable, depending on size and yield. Process approximately 120,000 lb/per month with a one-shift operation. This estimate includes maintenance downtime for blade changing and lubrication. The cutting mill is equipped with a premium efficiency IE3 60 hp motor. Add up to double capacity with the addition of our "Direct" or "XD Upgrade" or "XD Plus Upgrade" modules.

The power pre-fusing requirement is 125 amps, three phase 480V circuit. (400V 50Hz outside USA availabe). The mini-plant is shipped in one 40 ft. container, with only 4 hour on-site assembly required. Final installation assistance and training is provided by a Copper Recovery representative. Although compact in size, the cutting mill has an inner width of 20 inches, which facilitates easy conveyor feeding. Magnetic separator final conveyor with magnetic drum head is included as a standard feature.

Wire & Cable should be pre-sorted to achieve maximum output and in certain cases pre-cut, if not flexible, by means of a hand cutter or alligator shears. Smaller plastic cable spools, coils, bundles, and rats nests can be fed directly onto the in-feed belt conveyor. Engineered for an extremely long service life, this heavy duty machine offers multiple ways to achieve high production. Whether you choose to run it in shifts, Phoenix Cable Recycling Equipment is built to last.

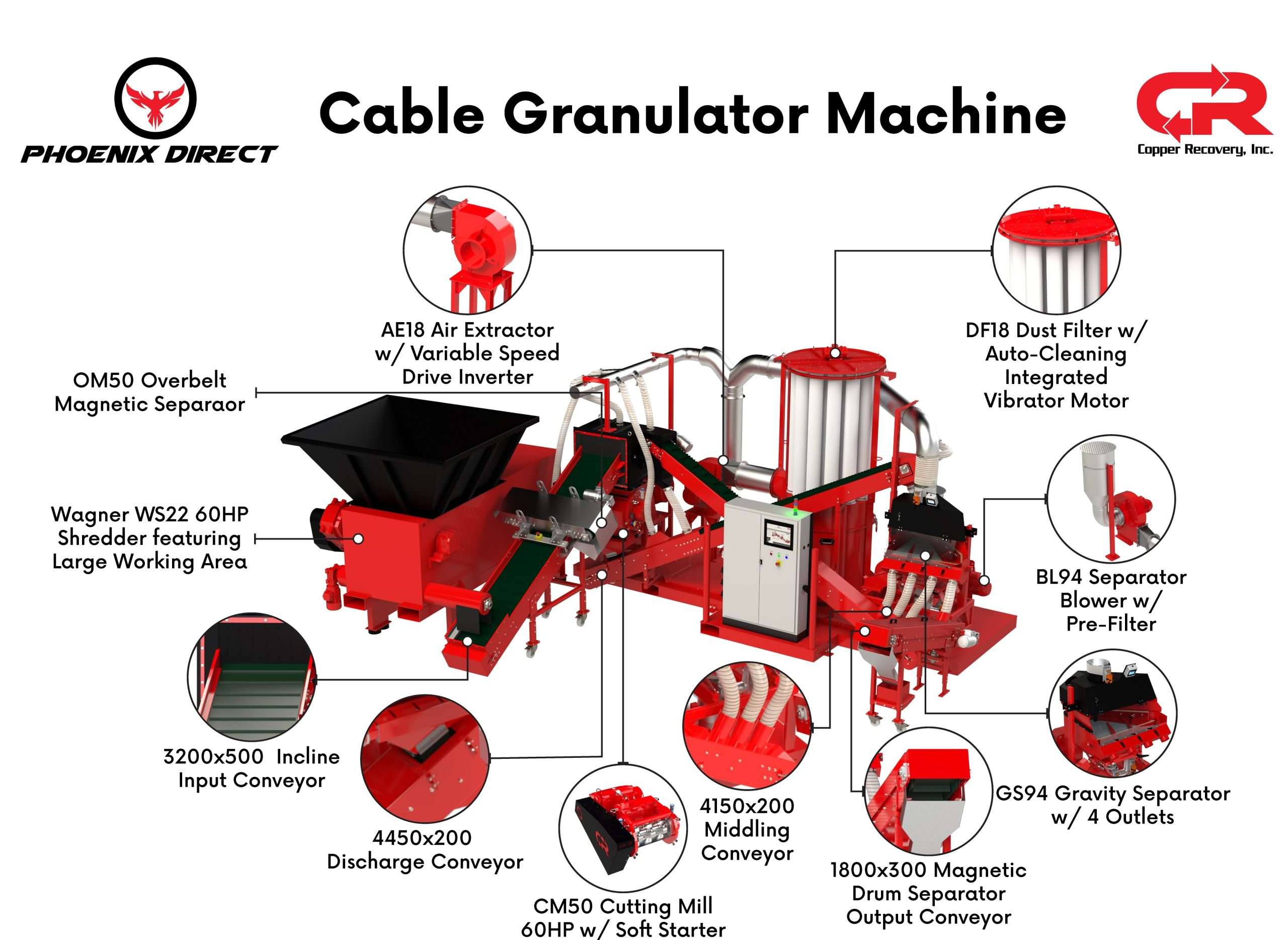

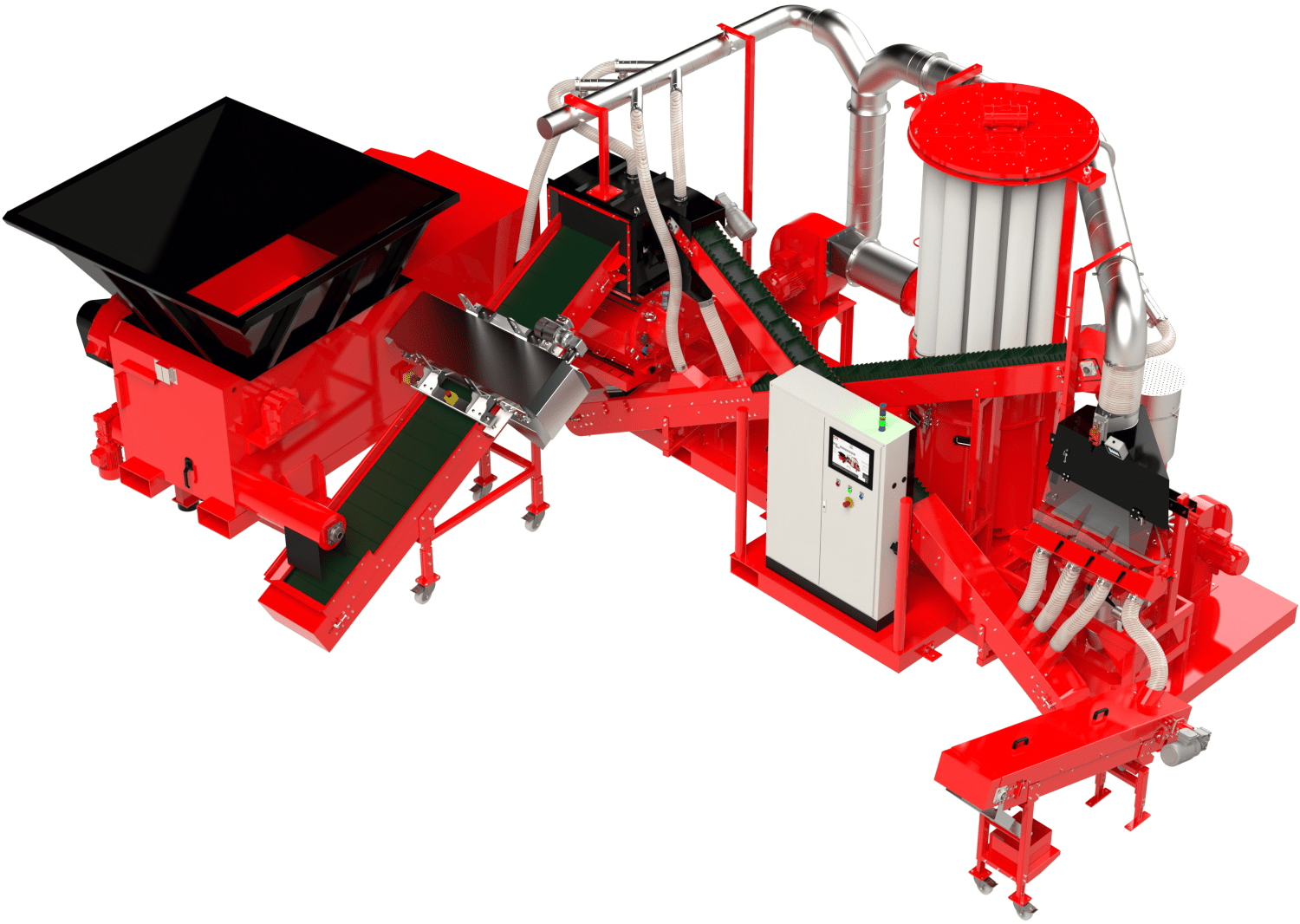

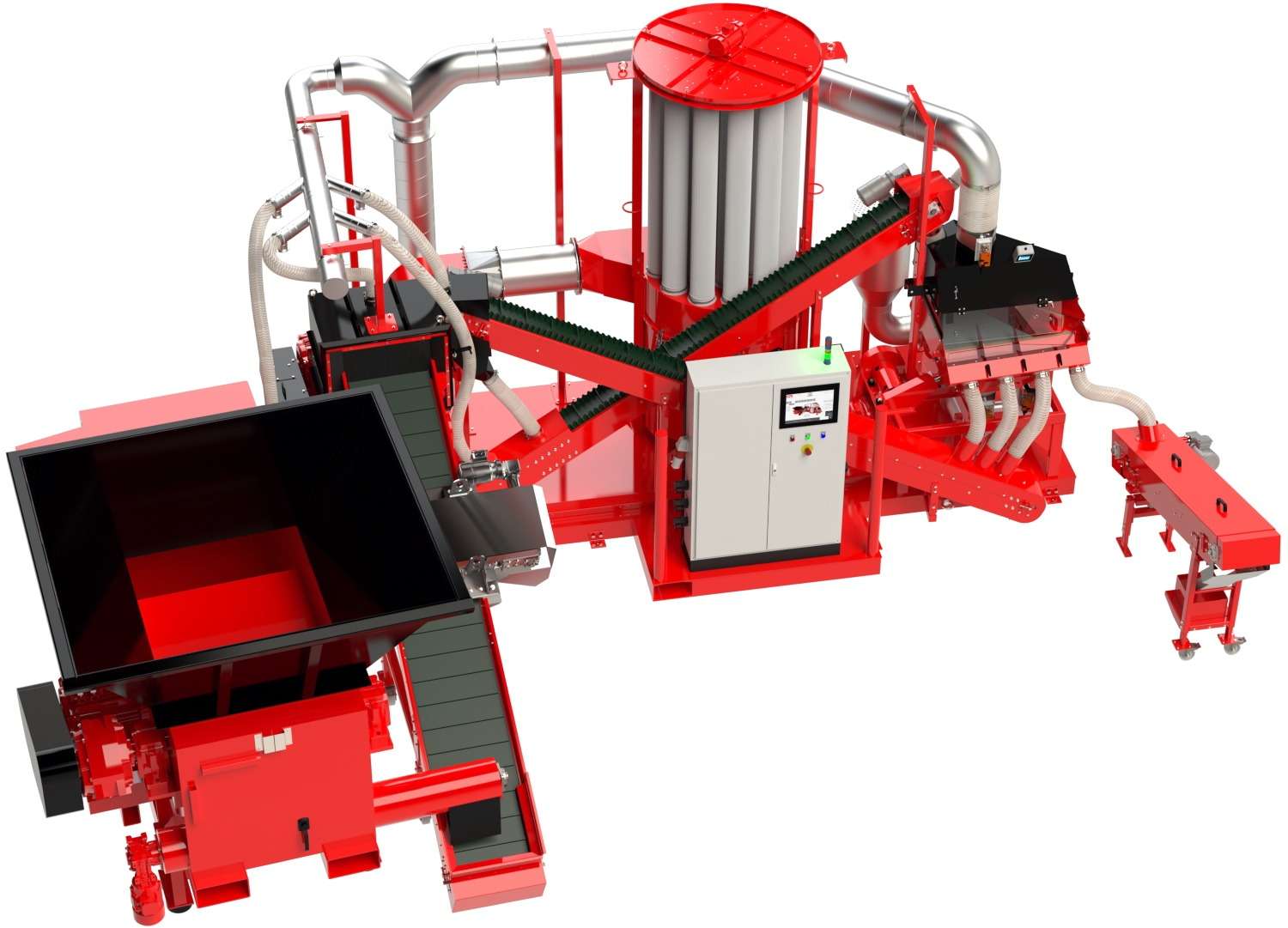

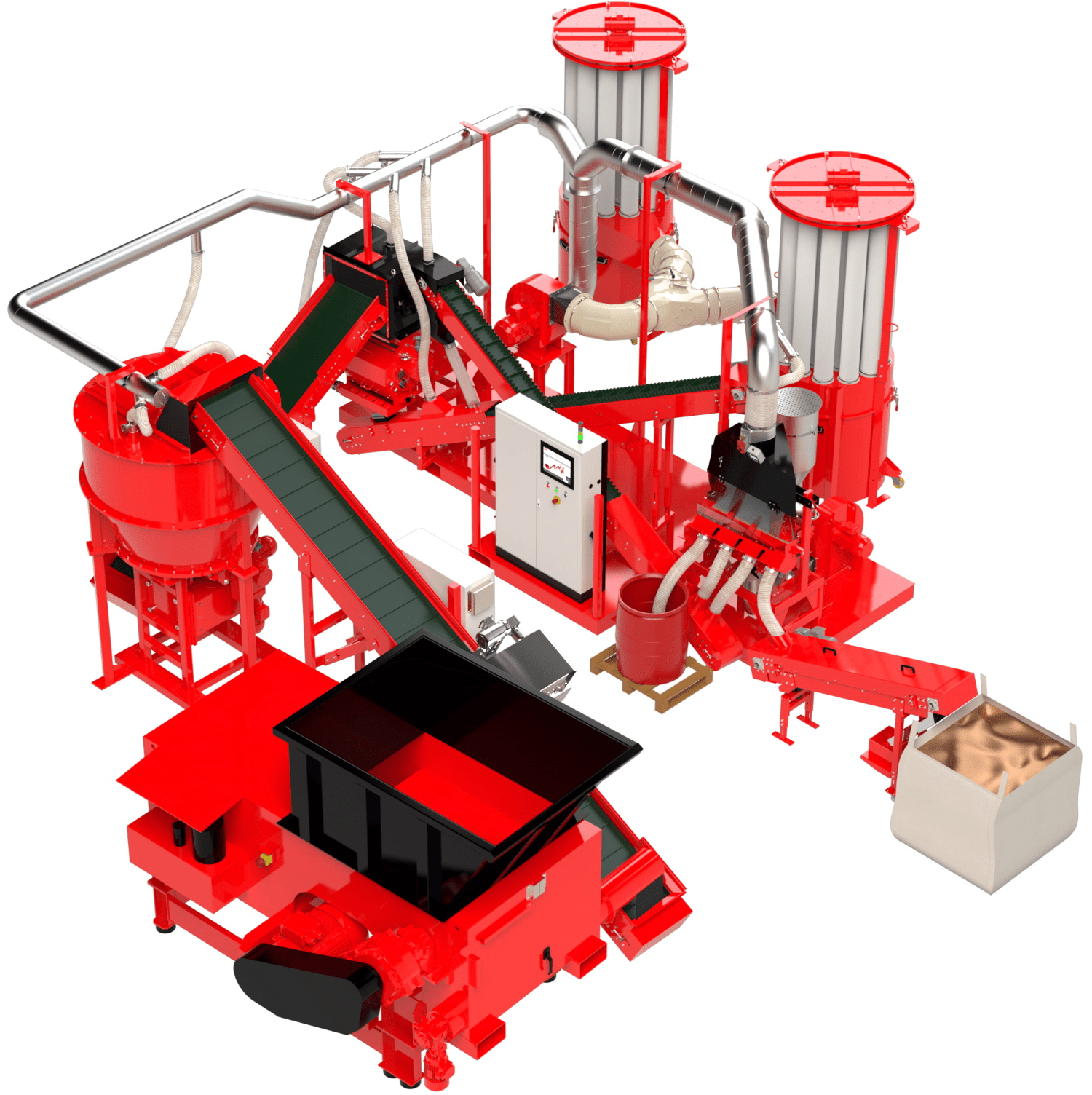

Phoenix DIRECT

Adds a Wagner WS22 shredder and OM50 Over-Belt Magnet to Phoenix

PHOENIX DIRECT is a professional turn-key cable recycling machine with the substantial capacity to process *1,200-3,000 input lb/per hour with mixed cable, depending on size and yield. Process approximately 180,000 lb/per month with a one-shift operation. This estimate includes maintenance downtime for blade changing and lubrication. The cutting mills are equipped with a premium efficiency IE3 60 hp motor. This "DIRECT" version adds a Wagner WS22 shredder to eliminate the need for pre-cutting. Larger screens are used in the shredder which subsequently reduces the time material remains in the cutting mill allowing for higher production. Addition of the shredder also eliminates the labor associated with pre-cutting material. Phoenix Direct is a one-man operation and consumes very little floor space.

The power pre-fusing requirement is 250 amps, three phase, 480V. One 125A circuit for Phoenix and another 125A circuit for the Wagner shredder. All components come pre-wired and tested from the factory. The cable recycling equipment is shipped in a 40 ft. sea container, or by truck depending on final delivery address. Only 8 hours of on-site assembly is required. Final installation supervision assistance and training is provided by a Copper Recovery representative. Although compact in size, the cutting mill features an inner width of 20 inches, which facilitates easy conveyor feeding. A specially constructed conveyor with over-belt magnetic separator protects the cutting mill from ferrous material after the shredder. All Phoenix configurations also feature a magnetic separator final conveyor with magnetic drum head.

Wire and cables should be pre-sorted to achieve maximum output and product purity. Plastic cable spools, large coils, bundles, and rats nests can be fed directly onto the shredder, about a gaylord worth at a time. Copper Recovery equipment is engineered for an extremely long service life, ease of operability all with the highest quality output product. This heavy duty cable granulator offers the highest production available on the market for the size. With a total height under 11', Phoneix Direct can fit just about anywhere.

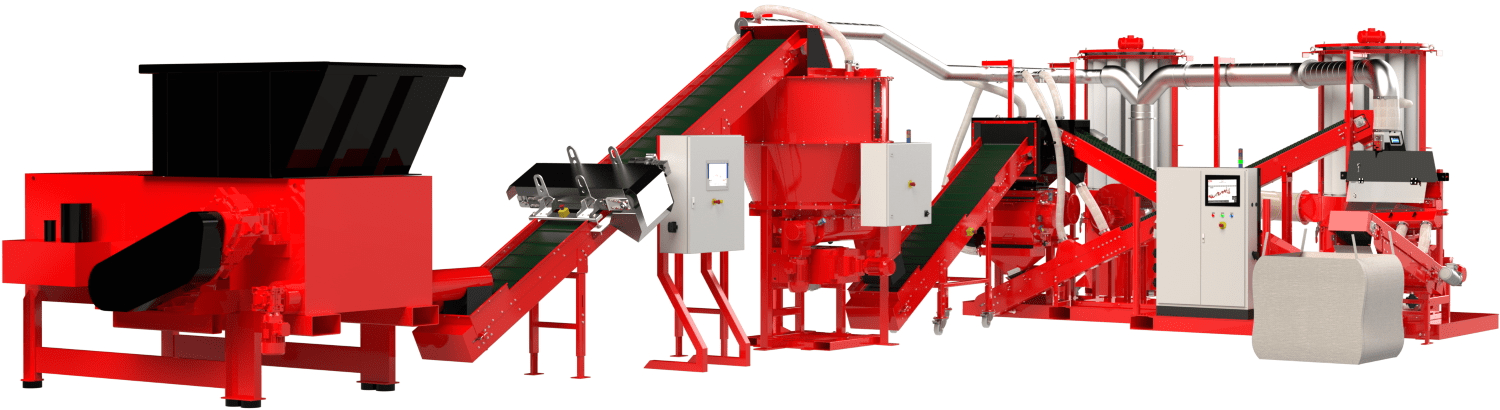

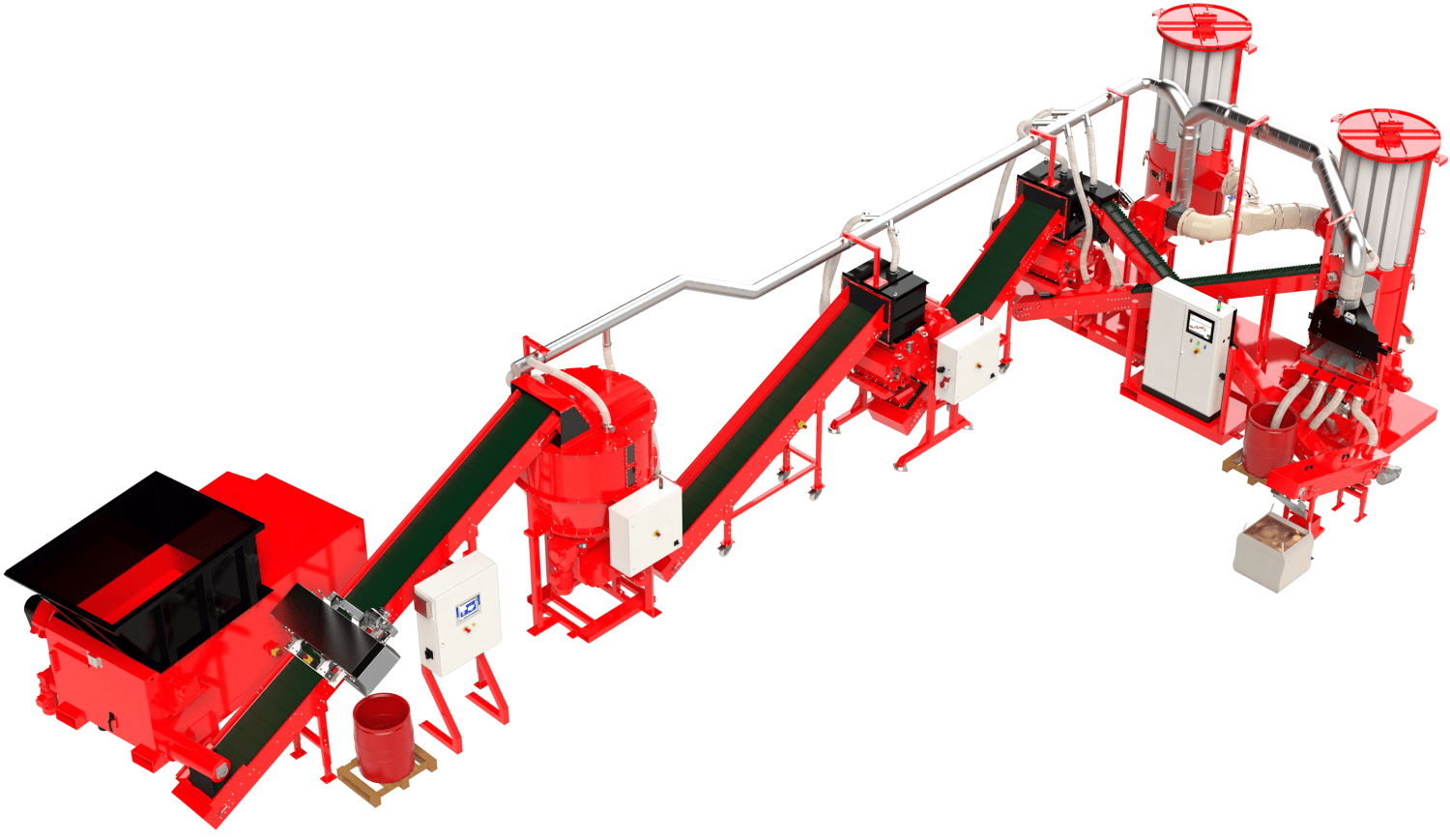

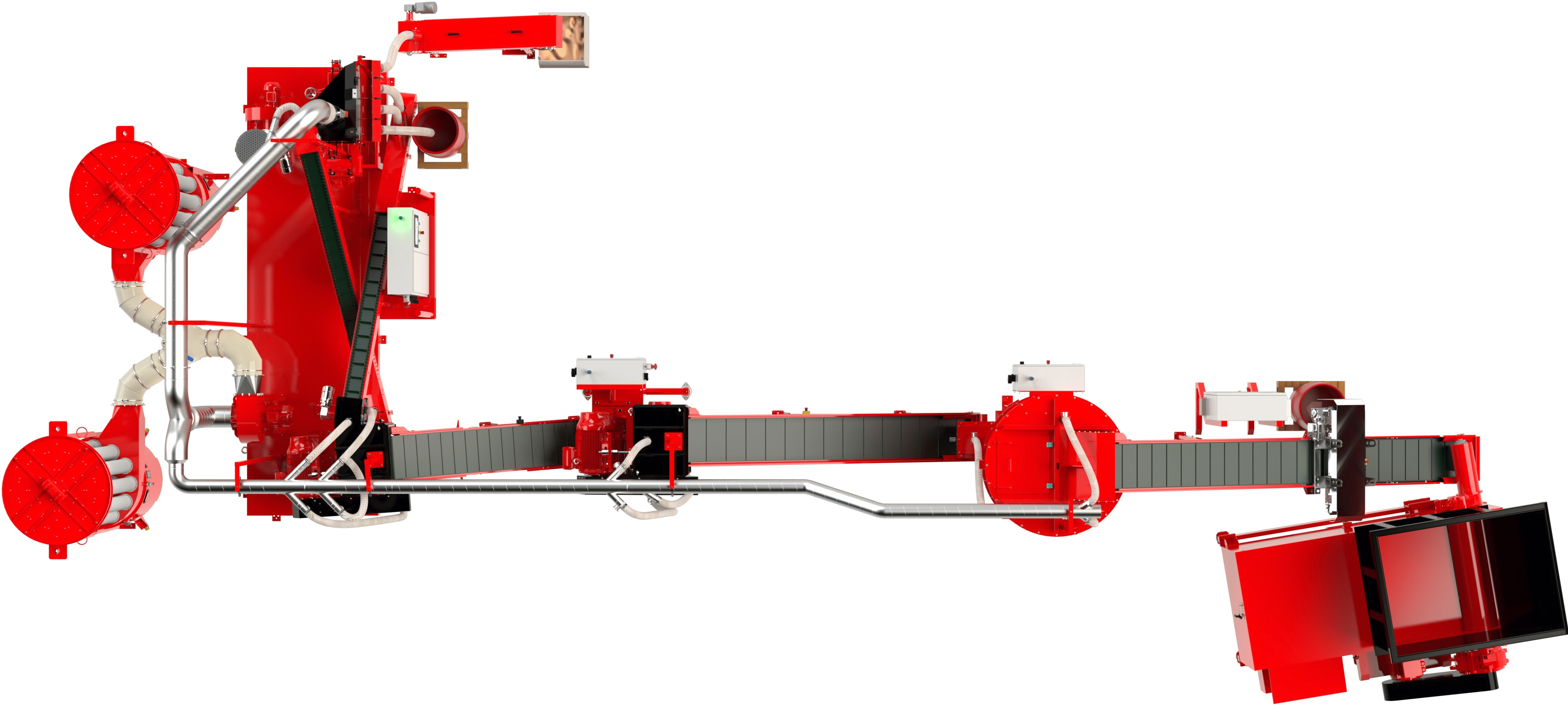

Phoenix XD

Automated Wire Chopping Line with Pre-Shredder and Variable Speed Dosing Silo

Double your capacity and halve your manpower with Phoenix XD fully automated wire chopping line. Our mini-plant, Phoenix, is upgradeable to Phoenix XD at any time with our "XD Upgrade" module. You never lose your initial investment if you first purchase Phoenix then decide to upgrade later, in fact over 60% of our customers go this route. The included Wagner WS30 60 HP Shredder features a large infeed hopper capable of handling large coiled material and gaylord quantity loads at a time! No pre-cutting necessary. No need to de-spool plastic spools.

SB15 Dosing Silo is a purpose built, 360-degree rotatable machine which features a variable speed discharge auger with oversized flighting. Helical Bevel gearboxes, shrink disk attached to an alloy shaft ensures high performance and long term reliability. SB15 serves as a buffer between the Shredder and Cutting Mill. Variable speed output allows the operator to optimize Cutting Mill production. SB15 is the key to maximizing productivity. Better than ever, SB15 is "Equipment Built for Production". Total plant power rating is under 200 Amps @ 480VAC, *270A of service required. (400V 50Hz 112 kW on request)

Phoenix XD ships in (1) 40' and (1) 20' container. Minimal on-site assembly is required. On-site installation assistance, machine operation training and process training is provided by a Copper Recovery representative and always included. We ran the old version of this plant for nearly 15 years. The new version is now used in our daily production and available for demonstration by appointment. Phoenix XD is vastly improved in materials, quality, and execution for an even longer life of profitable and reliable production.

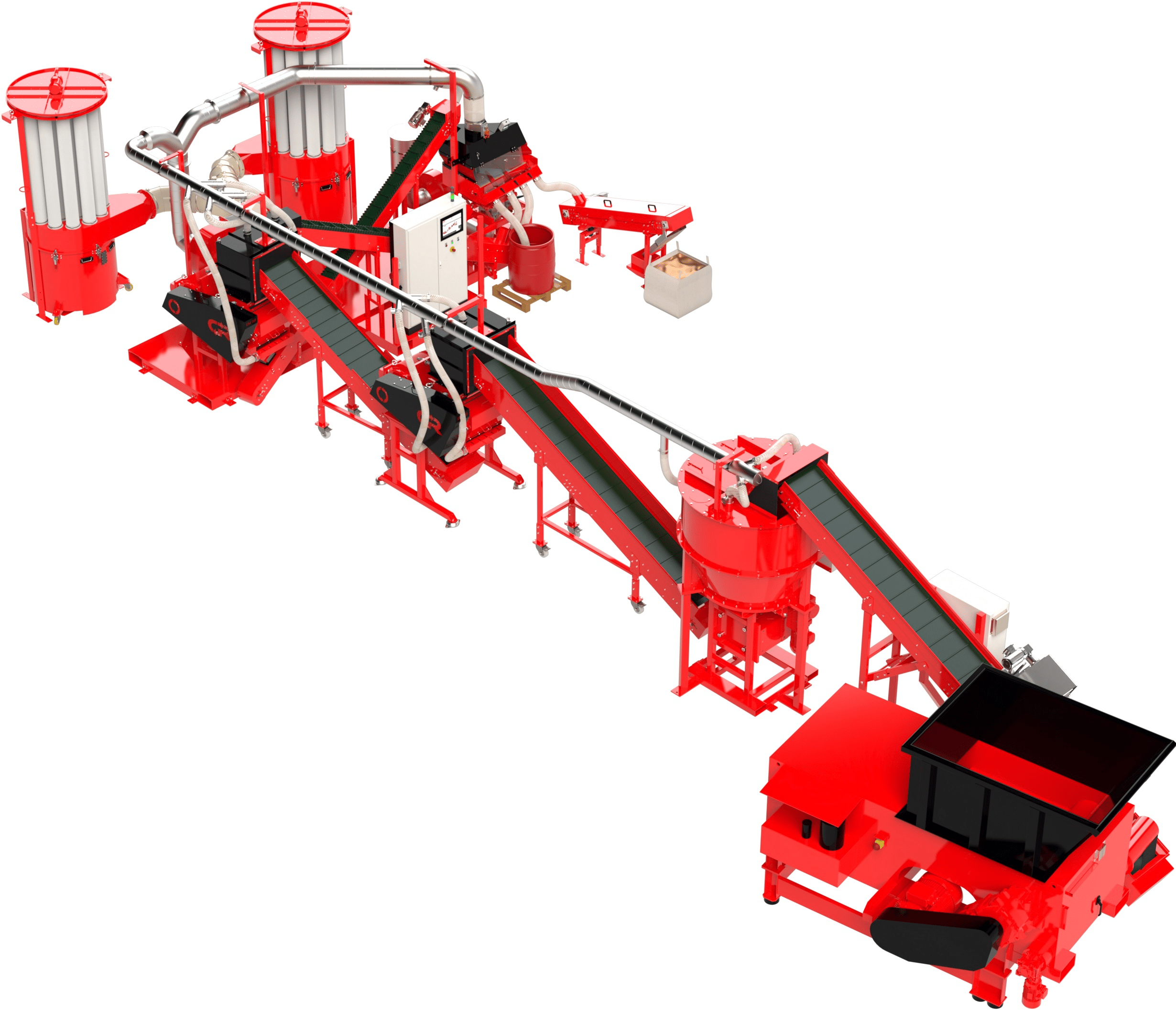

Phoenix XD PLUS

Automated Wire Chopping Line with Pre-Shredder, 2 Cutting Mills and Variable Speed Dosing Silo

Max out your line capacity with Phoenix XD PLUS fully automated wire chopping line. Our mini-plant, Phoenix, is upgradeable to Phoenix XD PLUS at any time with our "XD PLUS Upgrade" module. You never lose your initial investment if you first purchase Phoenix then decide to upgrade later. The included Wagner WS30 60 HP Shredder features a large infeed hopper capable of handling large coiled material and gaylord quantity loads at a time! No pre-cutting necessary. No need to de-spool plastic spools. "PLUS" indicates (2) CM50 60HP Cutting Mills.

SB15 Dosing Silo is a purpose built, 360-degree rotatable machine which features a variable speed discharge auger with oversized flighting. Helical Bevel gearboxes, shrink disk attached to an alloy shaft ensures high performance and long term reliability. SB15 serves as a buffer between the Shredder and Cutting Mill. Variable speed output allows the operator to optimize Cutting Mill production. SB15 is the key to maximizing productivity. Better than ever, SB15 is "Equipment Built for Production".

Total power rating is under 225 Amps / 480VAC but requires 370A of service. (400V 50Hz 149kW) Phoenix XD PLUS ships in (1) 40' and (1) 20' container. Minimal on-site assembly is required. On-site installation assistance, machine operation training and process training is provided by a Copper Recovery representative and always included. We have been running the old version of this plant for nearly 15 years now. The new version, Phoenix XD, is vastly improved in materials, quality, and execution for an even longer life of profitable and reliable production.